Shenandoah University Director of Augmented Reality/Virtual Reality (B.S.) Mohammad Obeid, Ph.D., with the assistance of SU students and staff at Shenandoah’s Center for Immersive Learning (SCiL), is developing a simulation platform that will train users in the assembly and assessment of industrial-grade drones.

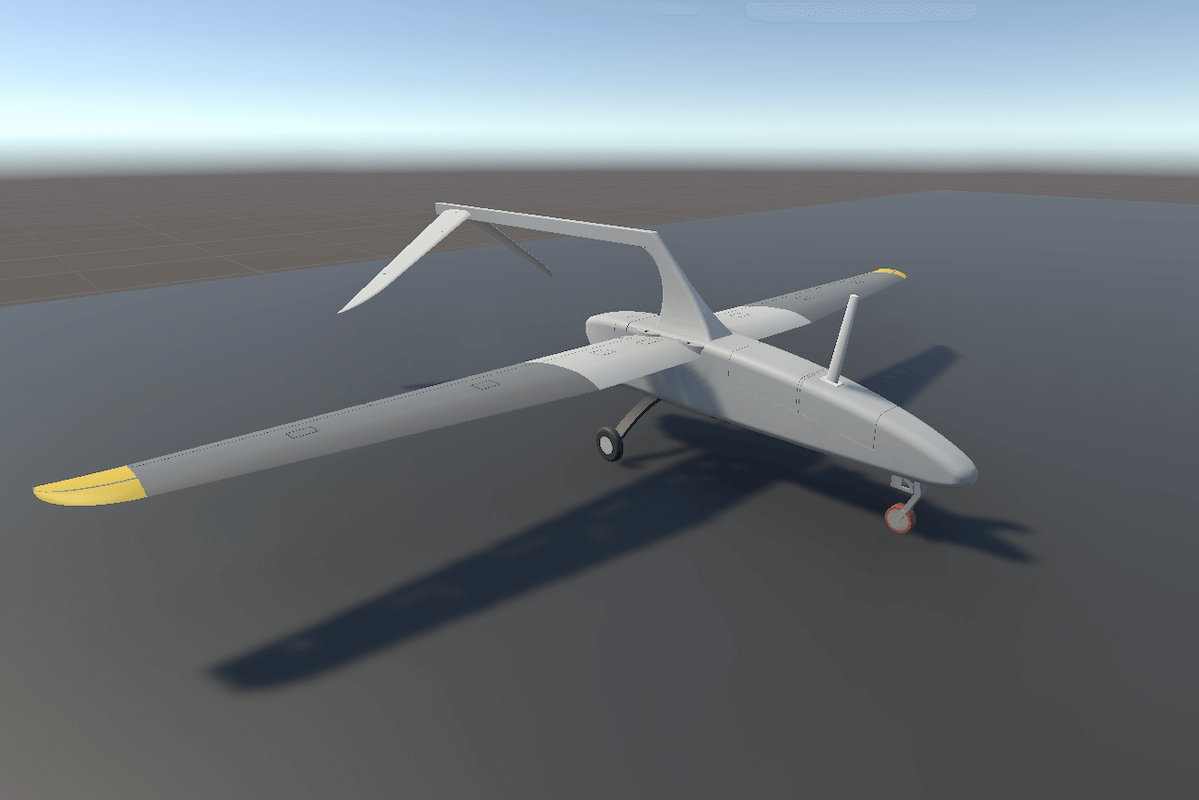

The virtual program will allow unmanned aircraft system (UAS) students at higher education institutions across the country to learn how to properly unpackage and assemble an Innocon MiniFalcon and assess its flight readiness. The platform eliminates the need to acquire the Innocon MiniFalcon drone, which is nearly 11 ½ feet long, has a 16 ½-foot wingspan and costs approximately $600,000.

This drone VR project is being supported by the National Science Foundation (NSF) through the National Center for Autonomous Technologies (NCAT).

We’re grateful to bring this innovative project to SU, allowing our students to harness what they learn in the classroom and implement it in a real-world setting for a well-defined user base,” Dr. Obeid said. “The simulation platform, when completed, will serve as a training and educational tool for technicians and students in many places nationwide.”

Mohammad Obeid, Ph.D., director of Augmented Reality/Virtual Reality (B.S.) and co-director of the SCiL Lab

Obeid hired two students – Michael Reynolds ’25 and Jacob Eisenhart ’25 – in Shenandoah’s virtual reality design program to help with the project, which is being created at the SCiL Lab.

Obeid hired two students – Michael Reynolds ’25 and Jacob Eisenhart ’25 – in Shenandoah’s virtual reality design program to help with the project, which is being created at the SCiL Lab.

“Having the opportunity to work on a research project in the SCiL Lab for an actual client has offered me insight into what it’s like to work on a project in the real world, and while working on this project, I’ve continued to refine my skills as a programmer and designer,” Reynolds said.

The Innocon MiniFalcon comes packaged in a 14-foot long container, and in nine pieces that require assembly. Students studying UAS technologies must be familiar with its assembly and be able to assess its flight readiness, which could include repairing its composite body with fiberglass or replacing malfunctioning avionics.

The virtual training experience will be set in an aircraft hangar and all assets, including the package, drone and tools, will be sized to real-life dimensions.

The program will feature three basic modes: learning mode, practice mode and assessment mode.

Learning mode presents the user with detailed, step-by-step instructions on how to unpackage, assemble and assess the drone for flight readiness. In practice mode, the user is presented an unopened package and must assemble and assess the drone for flight readiness without detailed instructions, though the user can ask for hints.

Assessment mode is similar to practice mode but hints are not available and factors such as time to assemble and inaccurate attempts are tracked by the platform. The experience will have a “finished” button so the user can report when they believe all tasks have been completed.

Assessment mode is similar to practice mode but hints are not available and factors such as time to assemble and inaccurate attempts are tracked by the platform. The experience will have a “finished” button so the user can report when they believe all tasks have been completed.

As part of the experience, users also will encounter random flaws that could be structural, which requires them to apply and sand fiberglass, or electronic, which requires the user to test various components to determine and fix the problem.

“Working on this project has already taught me so much about my major and has shown me what working for a real client is like,” Eisenhart said. “I have had a blast designing models for this project and I am excited to see the final build.”

The project is expected to be completed in Fall 2023.